0731-85221278

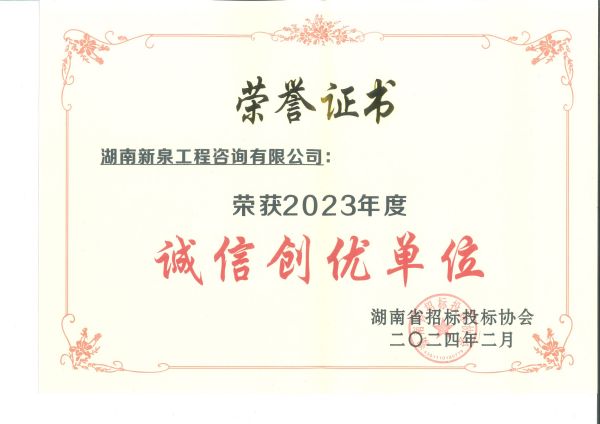

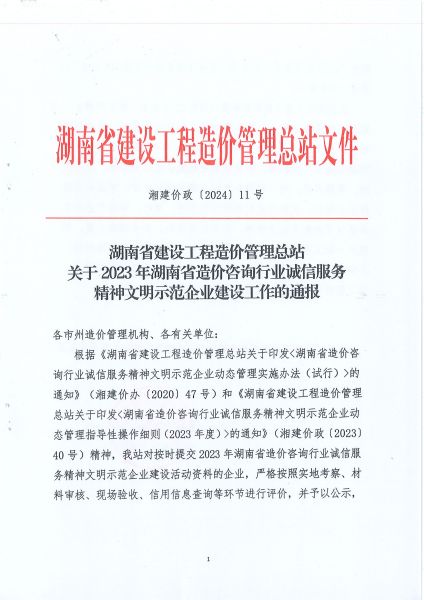

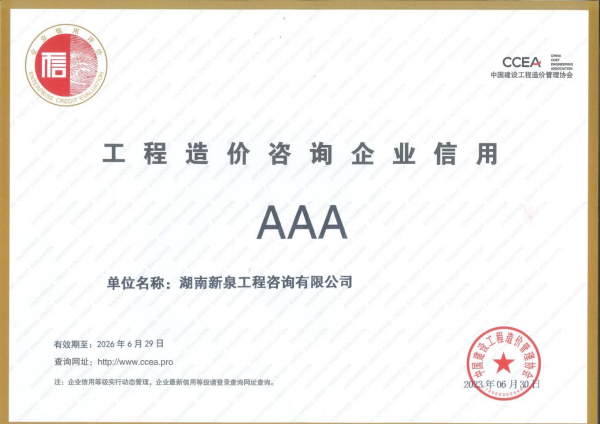

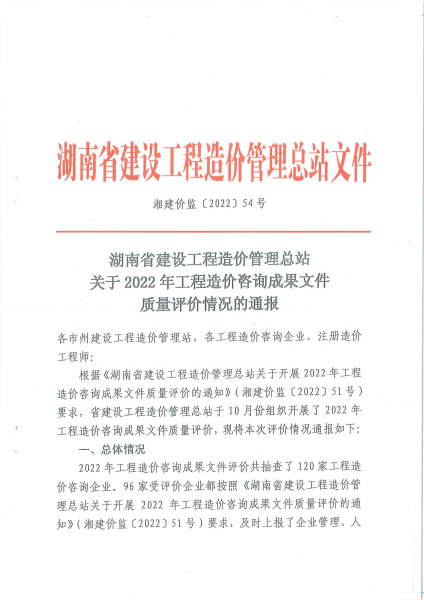

荣誉资质

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2020

08-1111

2020-0808-11

2020

2024

05-2727

2024-0505-27

2024

2024

03-2929

2024-0303-29

2024

2024

03-2828

2024-0303-28

2024

2023

12-2929

2023-1212-29

20232023

07-2828

2023-0707-28

2023

2023

03-1010

2023-0303-10

20232022

12-2222

2022-1212-22

2022

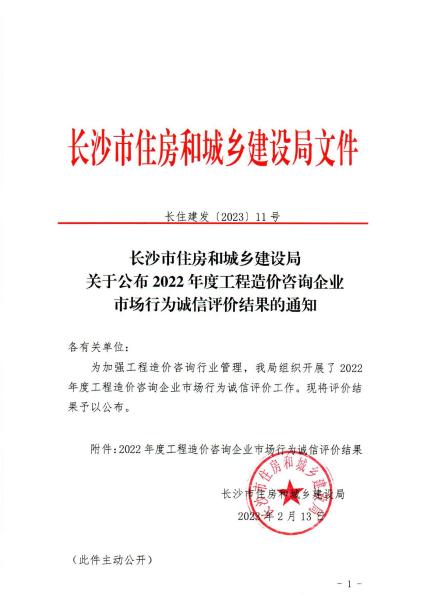

2023

02-2727

2023-0202-27

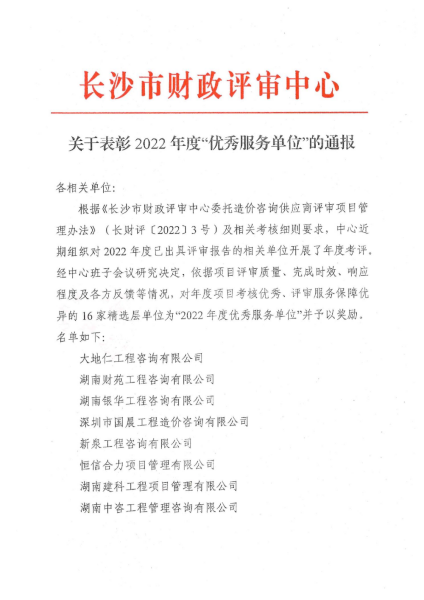

20232023

02-1616

2023-0202-16

2023

2023

01-2727

2023-0101-27

2023

2024

03-2929

2024-0303-29

2024

2024

03-2929

2024-0303-29

2024

新泉文化

2023

12-0404

2023-1212-04

2023

2023

11-3030

2023-1111-30

2023

2023

11-2020

2023-1111-20

2023

2023

11-2020

2023-1111-20

2023

2023

10-1717

2023-1010-17

2023

2023

10-1616

2023-1010-16

2023

走进新泉

致力于提供优质咨询服务

米兰平台,(中国)科技公司成立于2003年,一直精耕于工程造价咨询和工程招标代理领域,具备工程造价咨询甲级资质、工程招标代理甲级资质、政府采购代理资格、工程造价鉴定资格。公司服务范围包括:全过程工程造价咨询、工程项目管理咨询、园区(片区)开发咨询、专项研究咨询、招标代理、军工涉密业务咨询、司法鉴定、投资决策综合性工程咨询、项目中期评价、项目后评价、PPP咨询、绩效评价、决策咨询、管理咨询等咨询业务。公司现有在职员工180余人,其中高级工程师、全国注册造价工程师、造价员、招标代理专职人员等具有中级职称以上的专业技术人员100多人。员工专业技能精湛、执业品质优良、执业经验丰富。

公司以诚信为基础,注重公司队伍及品牌建设,着力提升员工的执....

企业动态

2025

02-2828

2025-0202-28

2025

2025

01-2020

2025-0101-20

2025

2024

12-1717

2024-1212-17

2024

2024

11-2929

2024-1111-29

2024